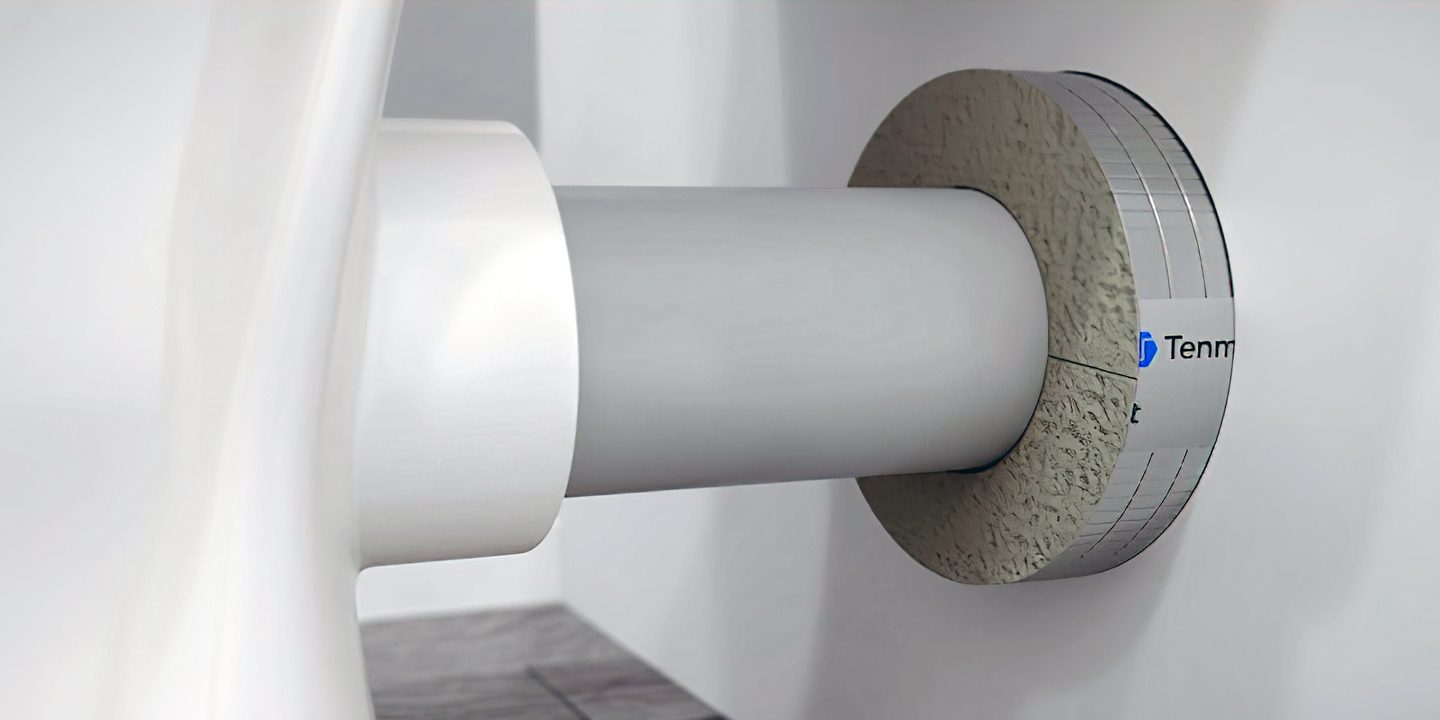

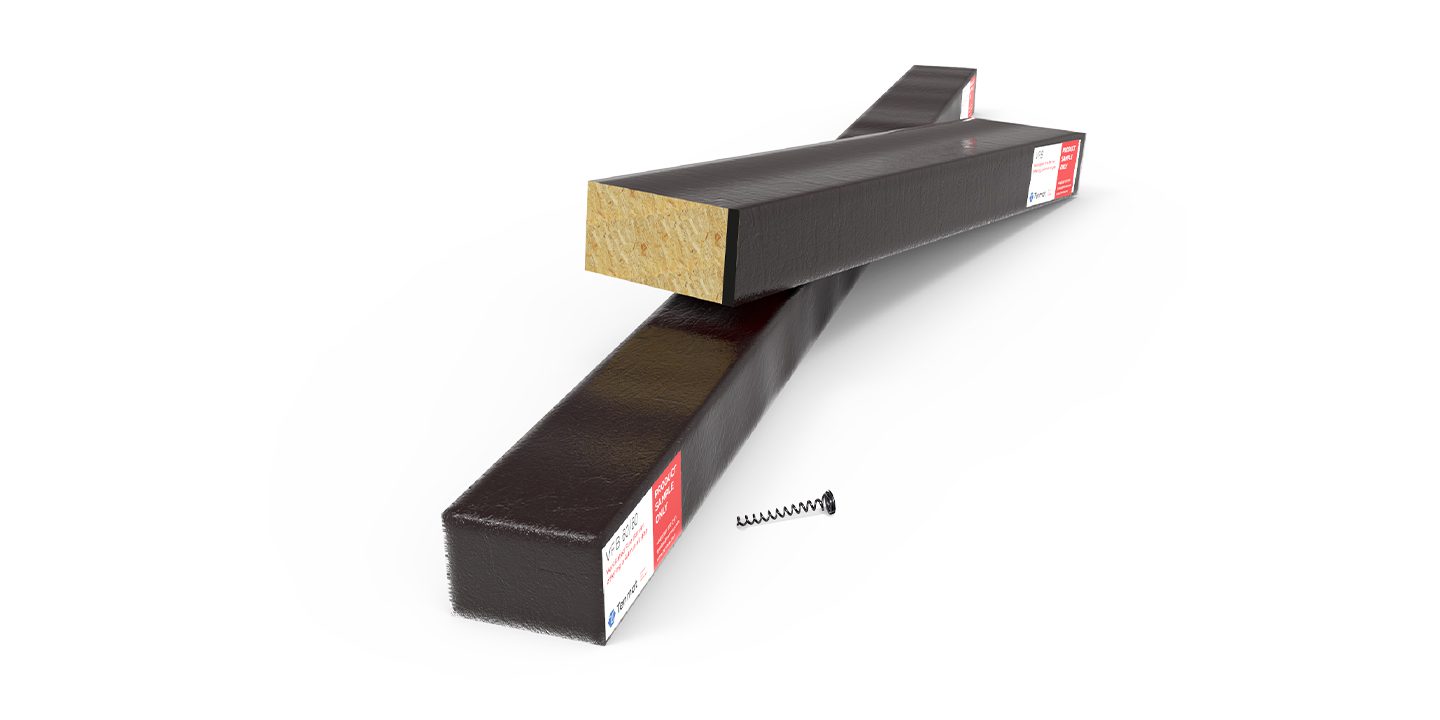

TENMAT FIREFLY millboards increase the working life of stopper arms, keeping them in service for longer by eliminating arm warping whilst also reducing gas consumption during preheat. They provide insulation for continuous casting to reduce energy costs by closing any gaps in the tundish preheat lids.

It is essential that a stopper arm’s functionality is unaffected by the radiation from preheating and from molten steel during casting. When a stopper arm warps, or “creeps”, a cast line can be lost for an entire cycle.

Customer Benefits

· Protects stopper arm from deforming

· Prevents issues with stopper mechanism

· High stiffness reduces risk of falling into tundish prematurely during pre-heating

The best protection possible

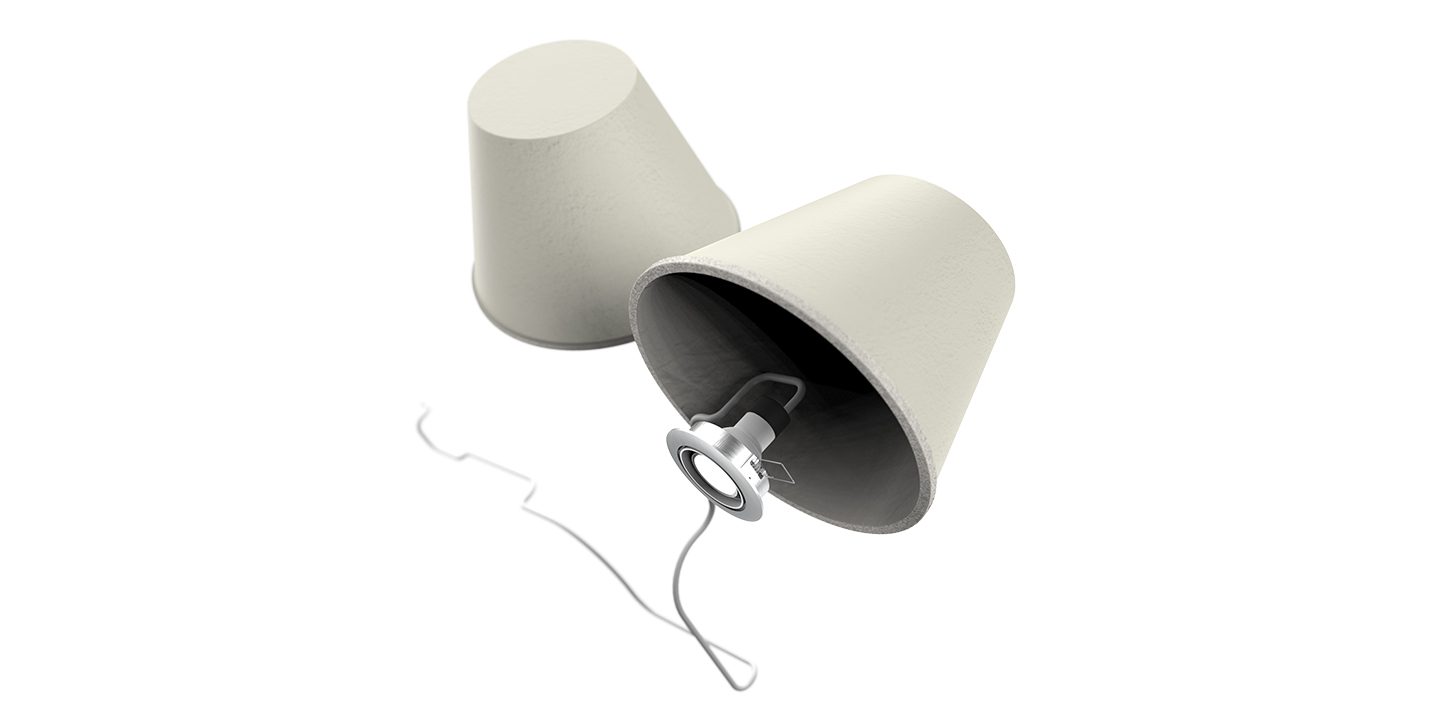

FIREFLY heat-shields are placed under the stopper arm to insulate against thermal radiation. They prevent the detrimental warping and bending which is seen when an arm is overheated.

FIREFLY has proved to be the strongest and stiffest heat-shield available. They outperform other solutions under the high temperatures of both pre-heating and casting cycles.

Key Features

- Excellent stability up to 1100°C

- Non-asbestos

- 100{b31dfa9a7c8099c314e960b46e483f159faba86f4e59565e93b438ccc25543d8} exonerated, non-ceramic fibre

- Superb thermal insulation

- Resistant to splashes of metal

- A1 non-combustible

- Very high dimensional stability

- Resistant to many minerals, acids, bases, solvents

- Superior performance-to-weight ratio

Please contact us HERE to enquire about all your High Temperature Materials needs.