Why choosing the right fire barriers is crucial

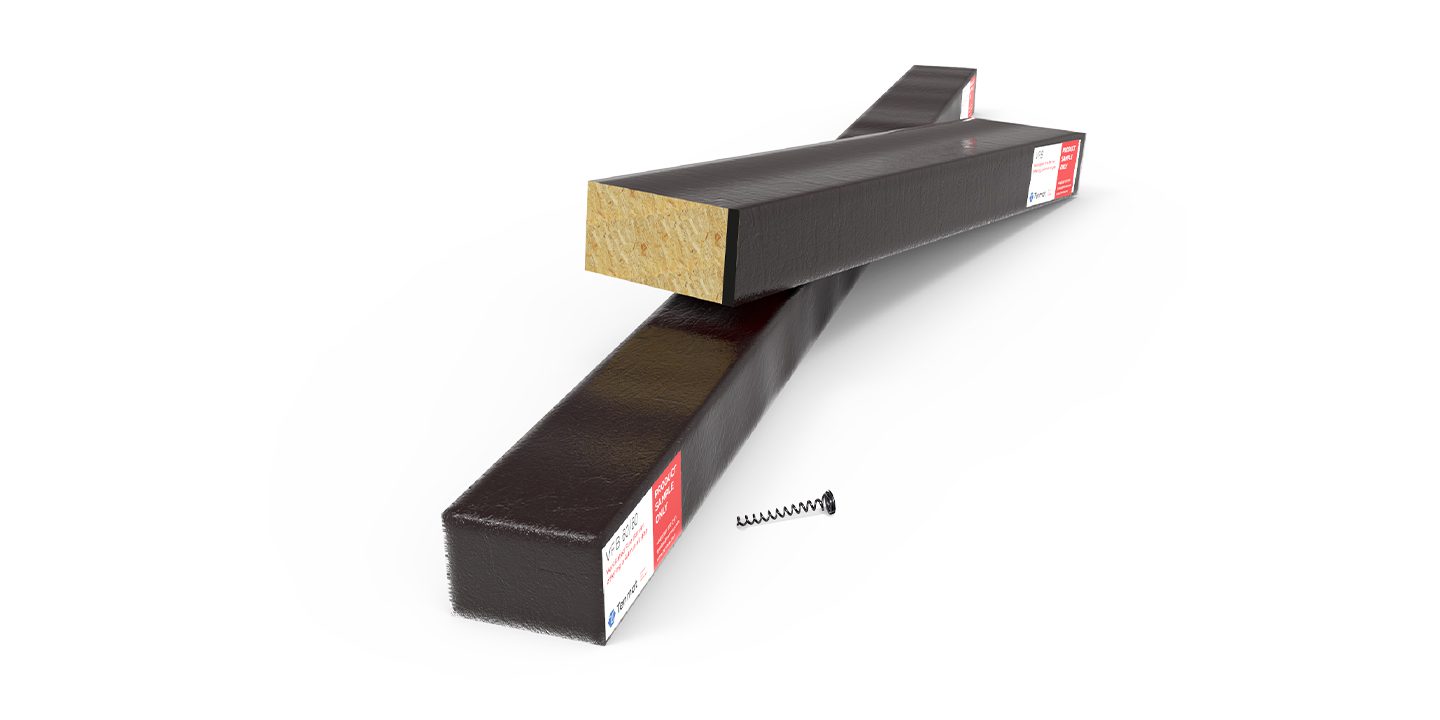

When specifying cavity fire barriers for a project, it may appear that choice is limited. Cavity barriers are usually manufactured from the same base material, stonewool, and broadly speaking they serve the same function – so it’s easy to assume that beyond the brand there isn’t much difference.

But the truth is that the value and performance of fire barriers varies greatly. Join us as we explore 5 reasons why you should choose Tenmat cavity fire barriers for your next project.

Barriers that last a lifetime

Something that truly sets Tenmat’s cavity fire barriers apart from others on the market is their extended working life. While most barriers have a working life of between 10 and 25 years, the active intumescent components used in Tenmat cavity fire barriers have a working life of 60 years.

This results in outstanding value across the full design life of the product and also significantly reduces the number of refurbishments required on installed projects.

The 60 year lifespan is attributed to:

Enhanced formula

Our intumescent is composed of a high level of inorganic content such as rock mineral fibres. This high proportion of inorganic material means the intumescent is more resistant to ageing.

Documented history of use

There are multiple versions of Tenmat intumescents used within our fire barriers that have been naturally age tested. This has enabled us to assess its performance across decades of use.

Testing

We have engaged in third party accelerated age testing and durability testing to rigorously assess how our intumescent performs when exposed to various environmental conditions and over prolonged periods.

Accumulating evidence

Testing isn’t only reserved for proving the lifespan of our cavity barriers; it’s central to our entire manufacturing philosophy.

Incoming raw materials are tested prior to being released for use in our ISO9001 accredited factory with further quality control checks continue during and after manufacture of the finished products.

Manufacturing only commences following rigorous third party fire testing of the cavity barriers at accredited fire test laboratories which proves the fire resistance performance of the products within a variety of representative construction build ups.

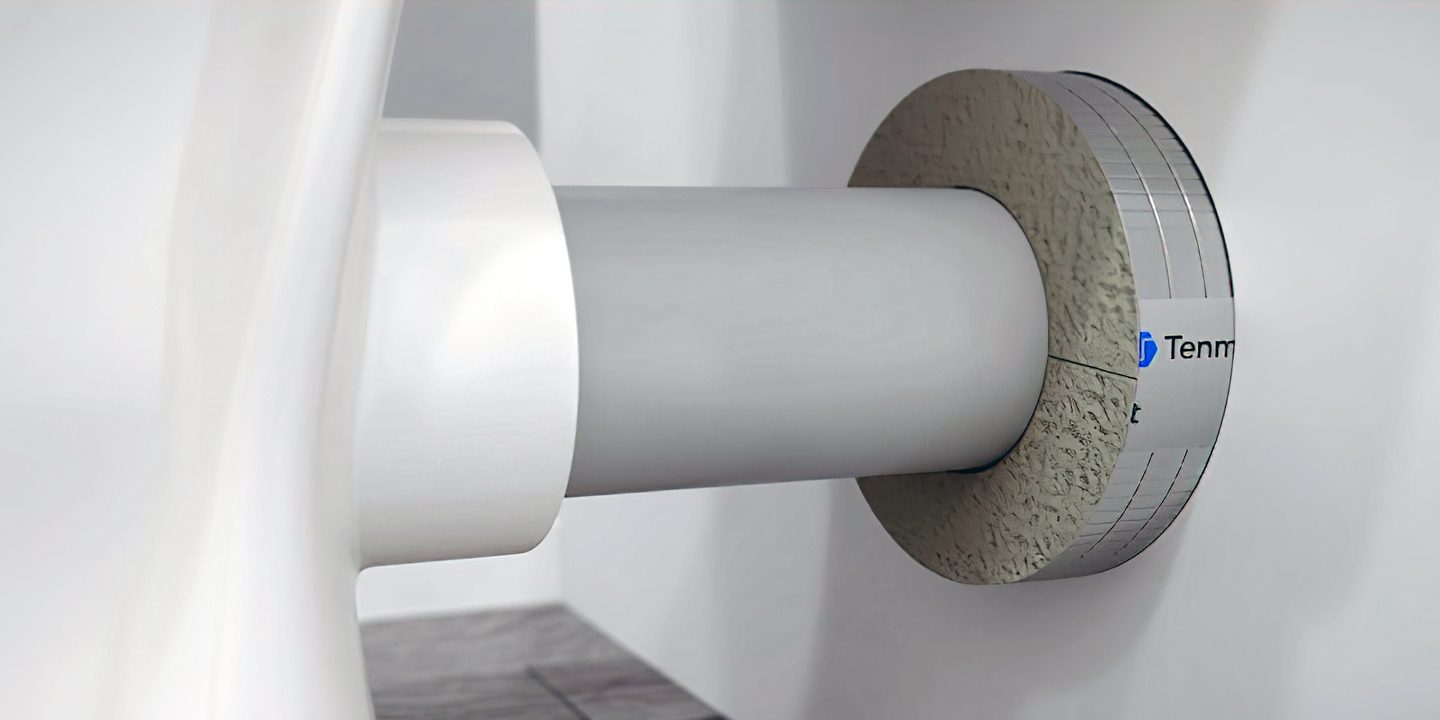

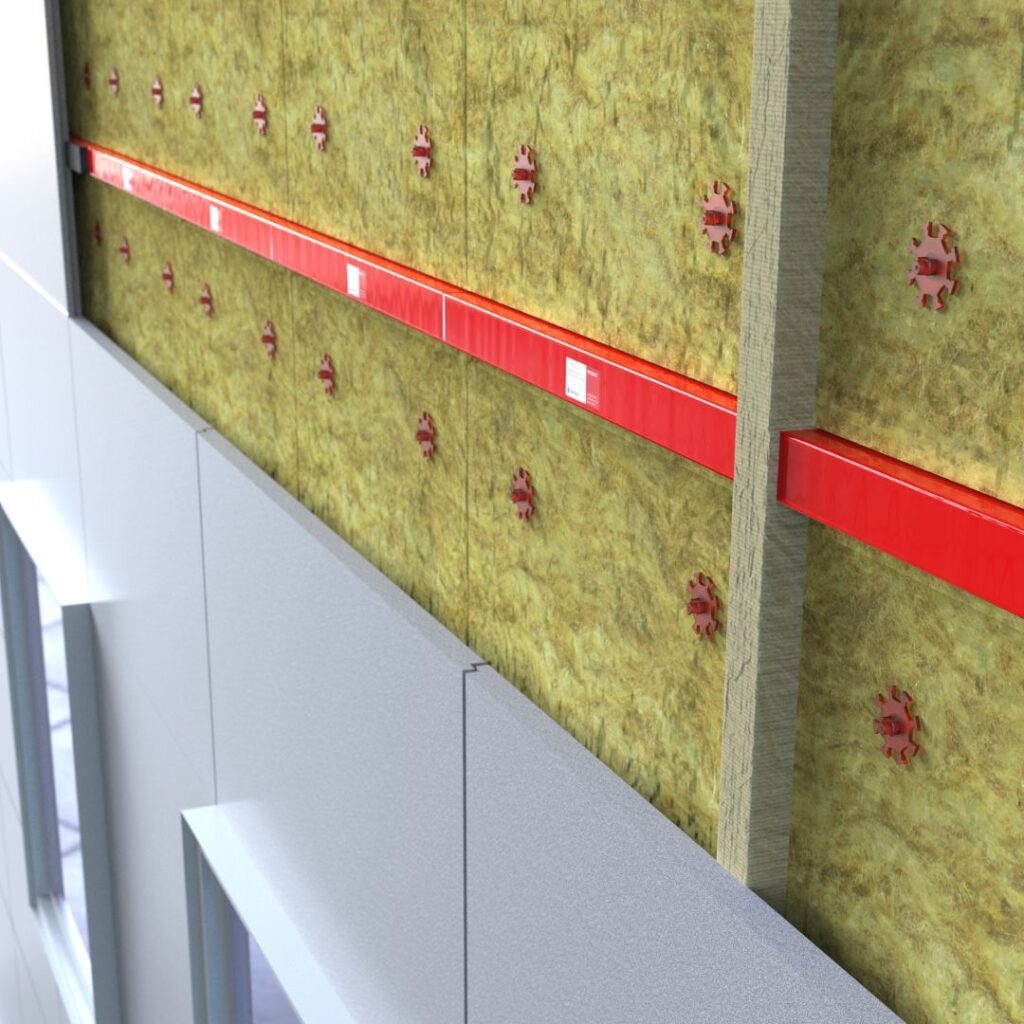

Filling the gap

A crucial component of our cavity fire barriers, Tenmat intumescent is manufactured entirely in-house following our unique formula. The active ingredient in this formula is intercalated graphite which rapidly expands when exposed to heat from a fire – forcing the fibres apart to form a matrix structure. In turn, this creates a stable and insulative char that limits fire spread.

While many barriers utilise intumescent that has an uncontrolled 3D expansion, requiring containment, the intumescent used in Tenmat cavity fire barriers has a uni-directional expansion – requiring no containment and working in one direction for the most effective and efficient cavity seal.

Interested in finding out more? Read our comprehensive cavity barrier guide here.

Reduced toxicity

Many barriers rely on polymer or rubber based intumescents which can produce large quantities of smoke and dangerous halogens when burned.

Conversely, the intumescents used in our cavity barriers have low smoke and zero halogen emissivity. This means that during a fire the level of smoke produced from our barriers is up to 40 times lower and therefore far safer than that produced by other barriers with higher smoke and toxicity levels.

With you at every step

In addition to the high performance of our barriers, it’s the service we deliver that makes us a top choice for countless building projects.

Our Specification Sales Manager Emily Naylor puts it best:

“Cradle-to-grave service is how we like to position ourselves at Tenmat. We are often asked where the support starts and ends; the truth is it stems from the early design stages with Principal Designers right the way through to supporting the installers on site and ensuring the client is happy with the work being carried out.”

Providing everything from design guidance to site inspections and toolbox talks, our service really does make the difference. Learn more about our offering here.

Choose Tenmat for peace of mind

There’s a reason why we’re one of the world’s leading passive fire protection manufacturers. From a manufacturing history spanning over a century to a commitment to investing in research and development that propels our industry forward, we are fully equipped to ensure your next project is a success.

Contact us to discuss your requirements.