PASSIVE FIRE PROTECTION

Exceptional materials, exceptional performance

Tenmat Firefly Intumescent Materials are technologically advanced passive fire protection solutions used in a wide variety of fire-stopping applications throughout the world.

Intumescent materials are most typically utilised within construction products to maintain or reinstate the fire resistance of buildings. For example, within walls, floors, and ceilings where the installation of penetrations and services can reduce the level of fire resistance, and intumescent materials or products containing intumescents can reinstate the fire rating.

Firefly Intumescents offer unique characteristics in terms of technical performance and the capability to be formed into bespoke finished components. Manufactured at Tenmat’s production facility in Manchester, UK, intumescent materials utilise intercalated graphite as the active ingredient as an alternative to intumescents using mono-ammonium phosphates or sodium silicate-based intumescents.

Our Intumescent Materials

FF102

Firefly 102 is a rigid intumescent material that possesses excellent pressure generation and expansion performance.

FF102B

Firefly 102B is a rigid intumescent material that possesses good pressure generation and mid-range free expansion performance.

FF104E

Firefly 104E is a dark grey intumescent paper which generates high expansion and expansion pressure when exposed to fire or heat.

FF107

Firefly 107 is an exceptionally powerful intumescent which combines fast reaction with high expansion and pressure generation.

FF108

Firefly 108 is a low-density, compressible intumescent material which exerts relatively low pressure and free expansion characteristics.

FF109

Firefly 109 is a compressible intumescent material which expands to form a resilient and stable char.

FF120 & FF130

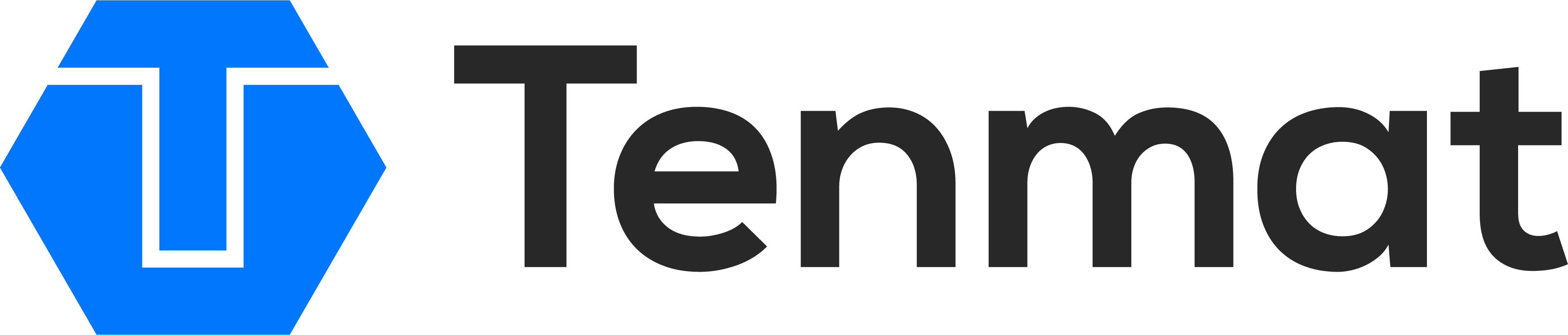

Firefly 120 and Firefly 130 are exonerated mineral fibre-based refractory materials which are used to reinstate fire and acoustic ratings and improve airtightness, in lighting and electrical socket penetrations.

FF160

Firefly 160 is an industry-leading intumescent material developed to provide outstanding expansion characteristics combined with an exceptionally solid and durable char structure.

INTUMESCENT MATERIALS

What are Intumescent Materials?

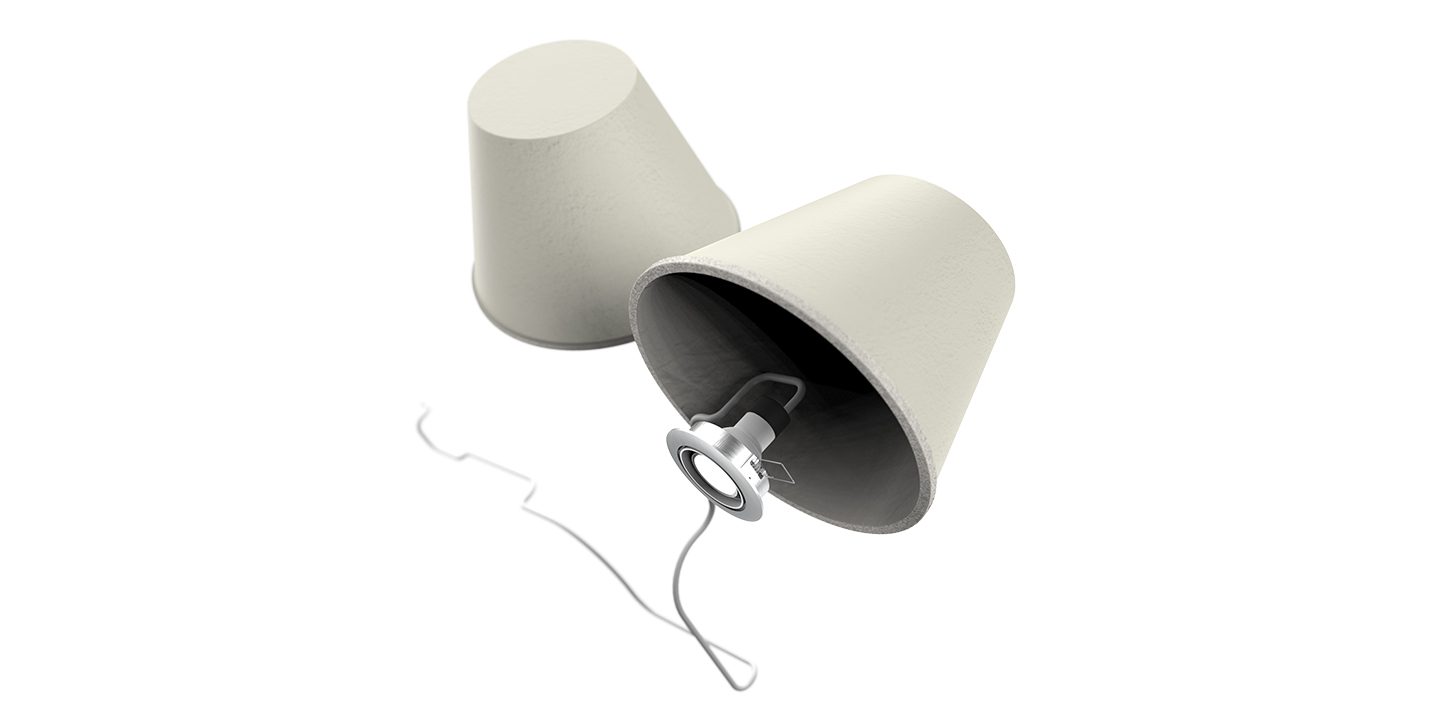

Passive Fire Protection is also referred to as fire compartmentation within a building, which ensures that fire cannot spread rapidly between compartments, relying on the integrity of its structures not being compromised. Penetrations such as pipes, ducting, lighting or electrical sockets compromise this. However, Intumescent Materials can be installed to seal off the penetrations in the case of a fire. Upon exposure to heat or flames, Intumescent Materials expand to close off the penetration and block the spread of fire, smoke and excessive heat. Intumescent cavity barriers can also be installed to compartmentalise an otherwise open-state, ventilated cavity.

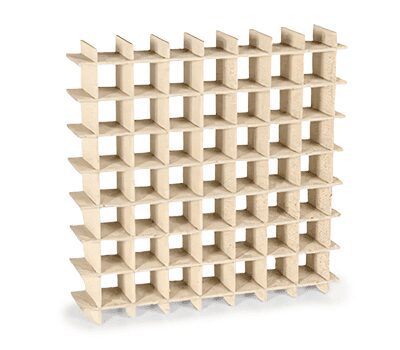

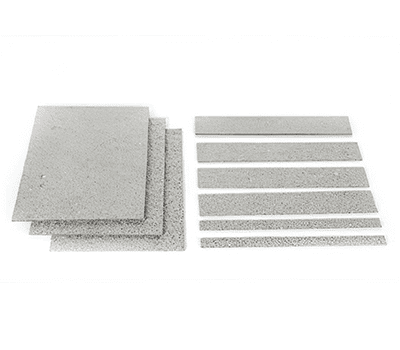

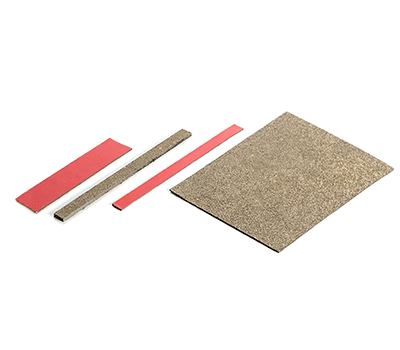

Availability

The materials are available in a range of sizes, thicknesses and shapes with expansion and pressure generation criteria to suit even the most demanding applications. The range includes flexible & rigid sheets, papers, grilles and unique vacuum formed shapes that provide technologically advanced and cost effective solutions to most fire stopping problems in the widest variety of environmental conditions.

Tenmat supplies a range of Intumescent Materials, each with performance characteristics suitable for different applications. With the strength of our research and development scientists, Tenmat are able to offer a wide range of intumescent materials and solutions. These include rigid intumescent (as seen with the FF102 and FF102B materials), compressible intumescent (such as FF108 & FF109) and flexible intumescent (such as FF104E & FF107) including in the form of intumescent rolls, sheets and strips. Tenmat’s Team of Research and Development scientists are more than happy to discuss specific customer requirements and to collaborate in order to develop solutions to even the most complex of fire stopping problems. See material pages for more information.