High-performance rotor vanes

Used around the world in vane vacuum pumps and compressors.

High-performance rotor vanes

Used around the world in vane vacuum pumps and compressors.

Feroform

Advanced materials for rotor vanes

Tenmat advanced materials are used extensively in rotary vane vacuum pumps and compressors throughout the world. Tenmat high-quality rotor blades are available in different grades and customised sizes according to customer-specific applications and environmental conditions.

Rotor Vanes

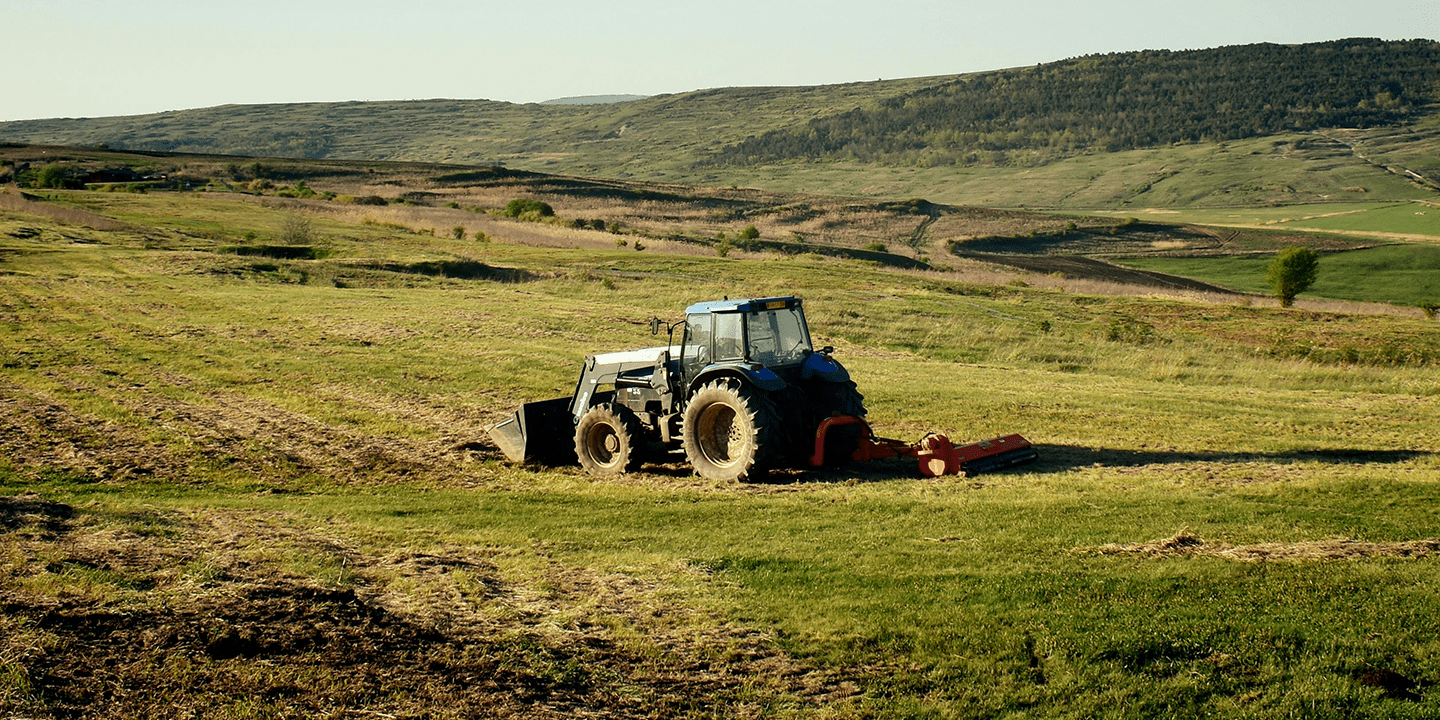

Medium duty vacuum pumps

Feroform AE2 and Feroform F57 are the materials of choice for all major milking pump manufacturers around the world. Tenmat rotor vanes are readily available in standard dimensions and can be manufactured according to customer specifications with lengths up to 1800mm.

Rotor Vanes

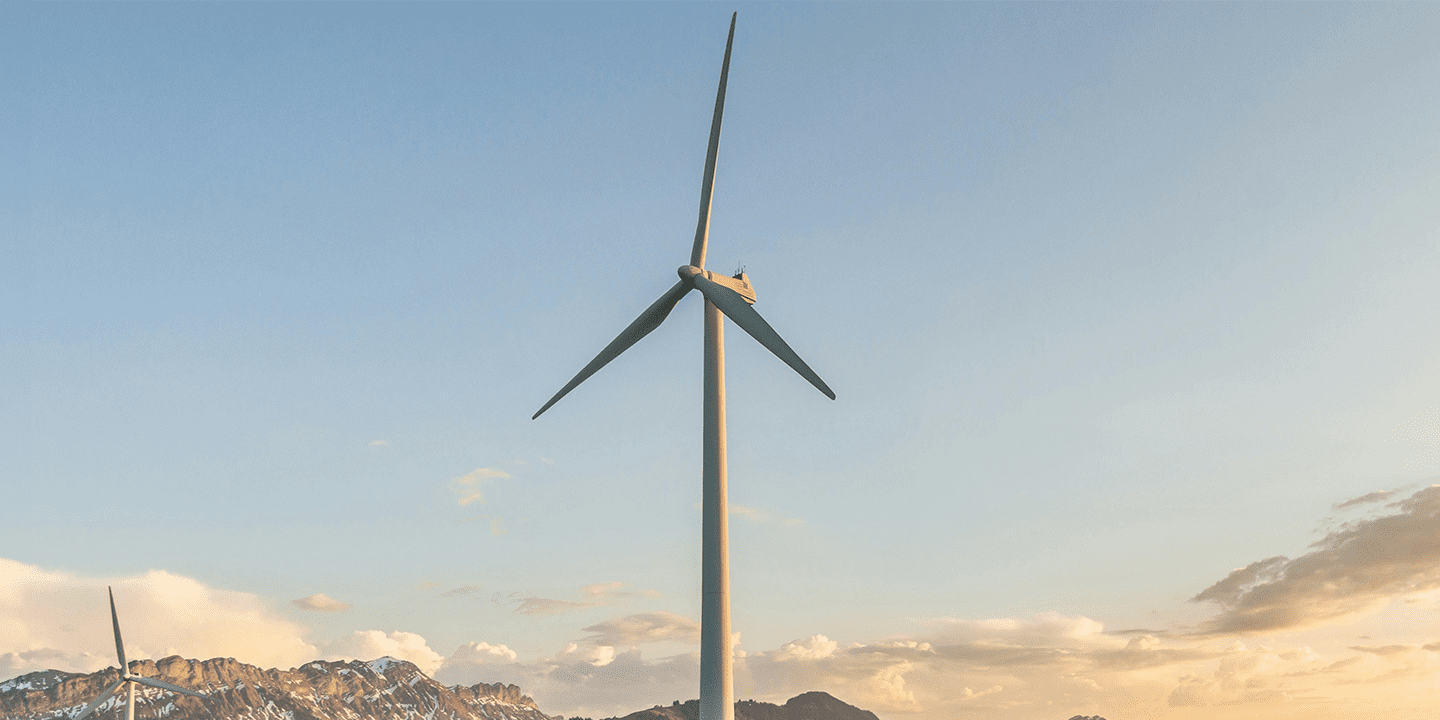

Heavy duty vacuum pumps and compressors

Feroform F57 rotor vanes are the industry standard for high-temperature (in excess of 200°C), heavy-duty applications.

Tenmat rotor vanes combine outstanding wear resistance with excellent dimensional stability. Due to their exceptional chemical resistance, Tenmat rotor vanes are the ideal solution for ammonia boosters and compressors within the refrigeration industry. Additional applications for long-lasting Tenmat rotary blades are tanker discharge pumps, pneumatic transfer air compressors and fracking equipment.

ROTOR VANES

High vacuum pumps

Feroform F43 rotor vanes were specifically developed for pumps with forced oil lubrication. The principal areas of use are in single and two-stage high vacuum pumps where Feroform F43 exhibits superb stability under vacuum, insensitivity to moisture, excellent strength retention, and low noise. Due to its unique microstructure, Feroform F43 can be machined to tight tolerances and extremely smooth surface finishes. Typical applications include rotary vane pumps on analytical instruments and mass spectrometry.

ROTOR VANES

High vacuum oil sealed

vacuum pumps

F44 rotor vanes are suitable for use in high-speed oil-flooded vacuum pumps. They are also considered future-proofed for the next generation of heavy-duty pumps.

Feroform F44 offers vast improvements in flatness, abrasion resistance, temperature resistance, chemical resistance, lamination strength, and flexural strength. One focus is long-term thermal stability. Laboratory tests prove that F44 is nearly 3 times more stable under extreme temperatures versus the next-best alternative. F44 retains significantly more flexural strength, even when exposed to 200C for 100 hours.

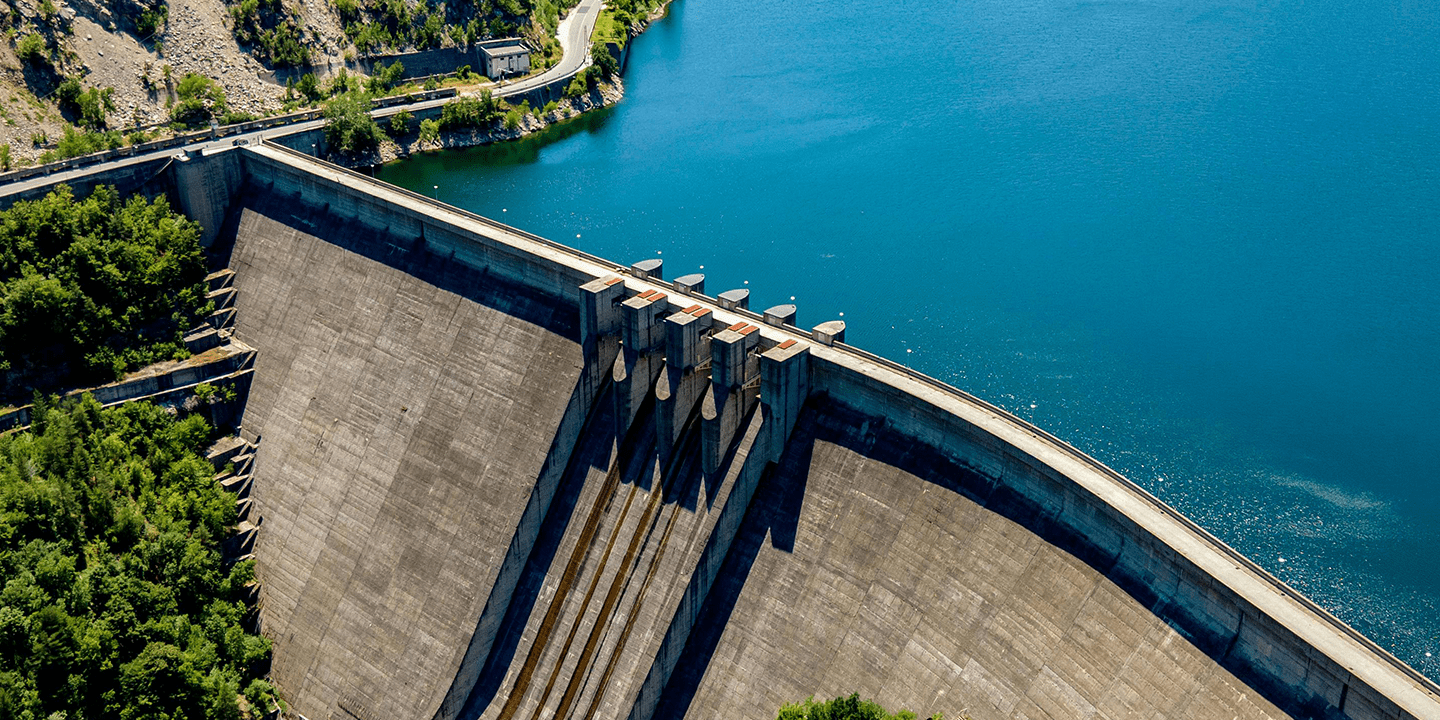

Rotor vanes

Dry running pumps

Tenmat’s Feroform F200A resin-bonded graphite rotor vanes provide outstanding service in demanding applications such as dry-running vacuum pumps. Tenmat’s speciality graphite blades are commonly used in environments where oil-lubricated pumps are not an option, such as hospitals, laboratories and in the food processing, as well as vacuum forming industry.

Long life and reliable performance are hallmarks of this quality product

- Long life

- Low noise

- Chemical and corrosion resistance

- Cool running

- High flexural strength

- High-temperature resistance

- Low water swell

- Wide pump operating range

Materials

Feroform AE2

Feroform AE2 is an economical, high-performance epoxy glass laminate used for rotor vanes for compressors and vacuum pumps.

Feroform F200A

Feroform F200A is a resin-bonded graphite which has been developed as a high-performance dry-running rotor blade material.

Feroform F43

With superb stability under vacuum insensitivity to moisture, excellent strength retention, and low noise, Feroform F43 is ideal for use in single and two-stage vacuum pumps.

Feroform F44

Feroform F44 has been specially developed as a solution for manufacturers of next-generation oil-flooded vacuum pumps, who need tighter tolerances, longer life, and better resistance vanes.

Feroform F57

Feroform F57 is a Kevlar-reinforced high-performance material for rotor vanes for compressors and vacuum pumps.